My YAMAHA P200 has been on the "operating table" (workshop) but she couldn't be saved, the dust cover was damaged, platter was missing! and the headshell/cartridge had also gone AWOL. Nothing more could be done for "her" so she has become an "organ donor" in the hope that some of these parts may give new life to another P200

It's like this ...

I am very "big" on sustainability, re-using or re-purposing equipment (no matter how trivial or old it may be) because a LOT of EE (Embodied Energy) was used to create this module and to throw something like this away, poison our landfill with plastics and a myriad of other manmade substances is just so irresponsible and such a waste of expended energy. Everything we humans have created required energy (and raw materials) for it's creation and often that amount of energy (EE value) is surprisingly high (Aluminium for example). So after using those raw materials and expending considerable energy to create an item, we then throw it away, burying it in the earth! Such terrible wastage.

Let's get down to the description of this set of motor related components from the P200

YAMAHA Model P200 Turntable (not the Electric Piano!)

Country of origin: Japan (this is not a Chinese assembled product)

SPARE PART ONLY - NOT THE COMPLETE TURNTABLE

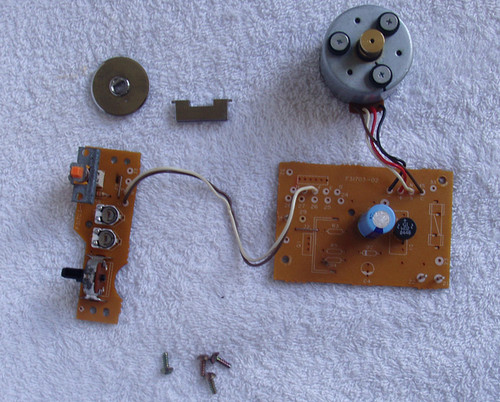

Part(s) offered (as pictured and described below):

DC turntable drive motor (dual winding, 4 terminals)

Motor identification: YAMAHA VC MOTOR JC-00077 VFB2R

Motor rubber mounting supports with bolts

Speed control PCB with two user adjustable trimpots (33 & 45 speed adjustments)

PCB identification: NA07948 LC7365

Speed select front panel switch (Push ON Push OFF locking) with top finger fitted along with the mounting bolt but NO user button - that button is available but advertised separately.

All wiring, interconnections are "as original" with none being cut or shortened in any way.

DIMENSIONS:

Motor: 38mm OD x 35mm height with brass section fitted to the spindle for the belt. Top of the motor body has 6x threaded holes for the mounting bolts although in practice only 3 are used.

Speed PCB: 77mm x 55mm single sided board

Speed Switch: 14mm x 8.75mm sub-miniature ALPS JAPAN dpdt (although wired as a spdt)

TESTING:

Without the platter being in place I had to test "with my fingers" - I know this motor was working fine previous to the platter going AWOL in any case.

The motor spins up fine and has a reasonable amount of torque, operating the speed switch did indeed alter the speed of spindle rotation. This speed control is perhaps one of the most basic you can get, no active devices on the board at all. The AC from the power module (Orange-Orange) wires supplies this board, this AC being rectified by the full wave bridge with a single filter capacitor, the resulting DC being supplied to the motor windings via the trimmer pots for fine speed adjustment. No feedback loops and certainly not precision speed control such as with a crystal frequency locked design.

COSMETIC CONDITION:

USED

Clean

NO damage to the motor, the PCB nor the speed select switch

All interconnection wiring and the PCB connection plugs are all in great shape

This "module" has now been placed onto a stiff cardboard backing and sealed within clear plastic to ensure its current condition is maintained.