INTRODUCTION

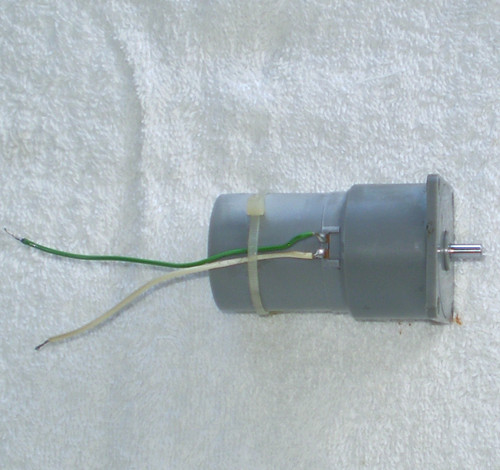

To most, the European specialised industrial control equipment this motor was extracted from is just junk - but look beyond the carcass of whatever you may be about to throw away and it is often possible to find a little gem inside, this is one of those "gems"

Sustainability is the name of the game! Anything (that has been tested and still functioning properly) should be repurposed creating saving in wasted Ee and reducing the poisoning our environment when items are buried in the earth at the local tip needlessly.

Never heard of Ee? It is a concept that creates a measurement of ALL things (not just electronics) that humans have made and the energy used in obtaining the raw material, processing the materials right through to a finished product and even should include the shipping of the item to the distributors/retailers.

If you would like to know more about Ee values, please take a lookHERE

HISTORY OF THIS ITEM:

Another salvaged part from some obsoleted European special purpose industrial equipment. No one is likely to be servicing the original equipment (EPROM failure) but the four factors which took my interest with this motor are: a) low voltage running 12V b) gearhead c) high torque and the nice solid 1/4" D shaft with Brass bushing.

This motor could well be an ideal candidate for the "experimenter" who can make use of such a motor in their own custom project.

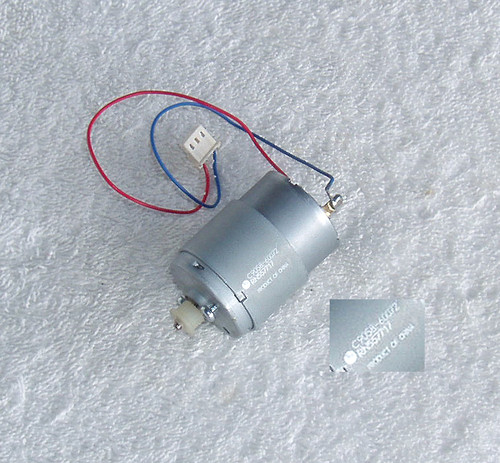

PHILIPS COMPONENTS - DC Motor With Integral Gearhead

Made In ?

Part # no longer readable

Completely thermo plastic encased but with this motor, in comparison to the Philips motors I extracted from the same equipment, this one has 3x long bolts securing the gearhead section. This means that if ever there was a desire to take a look inside, it should be possible - something that the Philips does not allow for.

Analog motion control i.e this is not a stepper motor - I used similar motors to these way back in the early days of designing some robotic systems, where the precision of using stepper motors was not required. This type of motor would have originally cost a small fortune!

Running voltage 12V DC

43mA running current (measured when powered in either direction)

Slow rotation of the 4mm OD steel shaft, measured at 60rpm

Gearhead is 200:1 ratio (printed on the body)

As mentioned above, it looks to be possible to get "inside" the gearhead although I haven't attempted this. Why? it would be good to know if the gearing is nylon or metal based. I cannot tell from "getting the feel" while holding the shaft, in fact it is very very smooth in rotation, as though the gears are sitting in a liquid! This motor was doing it's fair share of hard work in the equipment so it wouldn't surprise me if it used metal gears.

Hi torque

Low operational noise, when running it sounds like a cat purring! (even when stressed i.e when I try and stop the rotation manually, which I couldn't - this motor just keeps on turning no matter what) Just for interest sake, I also measured the current drawn when I attempted to stop the motor and it only rose to 75mA maximum.

NO solder terminals just short leads (Red & Black Red) used for the power connection.

Bi-directional movement i.e reverse the supply polarity and the motor doesn't object at all, Red to positive supply and rotation is clockwise, reverse this and of course rotation is anti-clockwise.

DIMENSIONS:

BODY: 55mm length

GEARHEAD: 27mm length x 38mm OD

MOTOR: 27mm length x 22mm OD

4x 2.8mm ID flange mounted holes at the front of the motor, this flange is 38mm x 38mm square.

Steel shaft is D shape with a 3.2mm hole drilled through it, 6mm OD x 15mm length

COMPLETE ASSEMBLY WEIGHT: 110g

TESTING:

Test supply was 12.1V DC

Rotational speed was measured at exactly 60rpm

Current drawn under normal operating condition was 43mA, maximum of 75mA under extreme stress (me trying to stop the rotation)

I do not have a torque meter so I just tried to stop the shaft rotation with my fingers - impossible! This little beastie just keeps on rotating no matter what, my fingers couldn't slow it down at all.

This basic information is intended to give an idea of the motor's suitability for your "project"