COMPANY HISTORY:

While you are likely to have heard of Revox and it's big brother Studer, Uher is not such a household name but in particular industries it was considered that to have an Uher was very desirable.

Uher (UHER Werke München KG) were an electronics design and manufacturing company that was founded in 1952 by Edmund Uher, later (in 1974) they were acquired by another company.

Uher specialised in portable analog tape recorder technology, making quite a name for themselves due to their product reliability and audio quality (the purpose for which they were designed)

They were up against the pinnacle of portable tape recorders, Nagra, and Uher's could be found in the media industry (reporters), film, law enforcement and it is said, espionage.

This 9500 was designed and released just prior to Uher being sold to another company Assmann GmbH (nothing to do with the well known conversation on a Seinfeld episode - I have one of those plates too!)

Assman GmbH is now the copyright holder of the Uher name and company logo.

Because Uher's target market was within specific industries, not many Uher's found their way into the domestic scene - they are extremely hard to find now, particularly the larger models such as this 9500 and the 10,000

With the advent of digital technology, analog tape recording equipment died and Uher no longer had their traditional markets.

MACHINE HISTORY:

I ran an audio post facility for 25+ years, one division was heavily involved in the world of reel to reel tape recorders (for archiving historical tape based material). I was always on the lookout for high quality machines (yes, I am a "tapehead") with most of our professional activities using our Studer B67's and the wonderful A810/820's. This Uher was obtained while in UK/Europe from an associate, more for personal fascination than use in our business - it has some nice features which are detailed below.

As luck would have it, I never powered up this machine! Too busy and now a further 20 years on, I don't think I am ever going to use it or at least appreciate what it can do. It's time to find a new home, someone who appreciates such things and hopefully can put it to use.

It has always been kept dry and protected from dust.

So let's get down to specifics ...

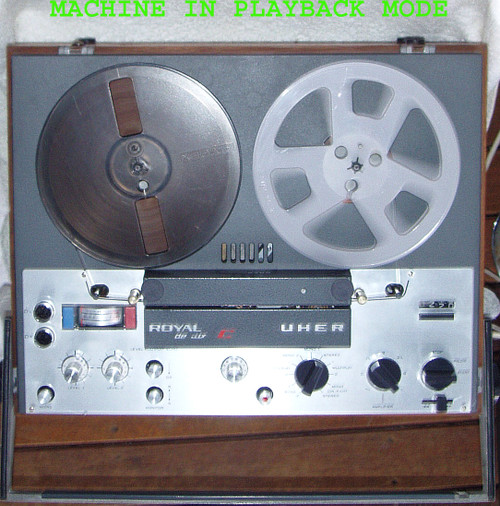

UHER 9500 Royal Delux C Tape Recorder

Designed and made in West Germany (this was at a time when Germany was not unified)

Released to market 1972 - 1973

Designed for operation Upright, Horizontal or at an angle from the vertical

AC input: selectable multi-voltage 110 ~ 250V 50/60Hz

AC power consumption: 50VA 45 Watts

Supplied set to 240V 50Hz operation

2 metre power lead with an ELMACO white plastic plug (Australian manufacturer of plugs in the 1970's)

NOTE: This equipment was designed as a 2 wire power system, NO EARTH wire. It really should have a 2 pin plug on the end (like a double-insulated lead) OR fit a 3 wire lead and connect earth to the equipment inside.

1/4" media up to 7" reels

Speeds:

15/16 ips (20 ~ 5Khz)

1 7/8 ips (20 ~ 9Khz)

3 3/4 ips (20 ~ 15Khz)

7 1/2 ips (20 ~ 20Khz)

Frequency response (3dB points) is as quoted by the manufacturer

The slowest speed is intended for long record times with acceptable speech recording quality

The highest speed is not too bad and fine for non-demanding recordings

Wow & Flutter quoted as ranging from 0.05% (highest speed) to 0.4% (lowest speed)

Signal/Noise Ratio (unweighted) -52dB ~ -51dB

These figures are pretty impressive for a 1970's analog tape machine

All audio input & output connectors are DIN standard using the 5 pin connector

Microphone input (Left and Right - two separate sockets located on the top left-hand side0

Low impedance (200 ~ 500 Ohm)

Level: 2mV

5 pin DIN female

All of the following connectors are located UNDERNEATH the machine, slopping panel

Aux input socket - rear panel (underneath)

200mV ~ 10V input level

47K Ohm impedance

5 pin DIN female

Input & Output socket - rear panel (underneath)

Input 1: 2mV ~ 1V

47K Ohm impedance (pins 1 & 4)

Input 2: 50mV ~ 10V

1M Ohm impedance (pins 3 & 5)

Output (when in playback mode): .775V

15K Ohm impedance

5 pin DIN female

Left audio output - low level (this will drive headphones but NOT a speaker on this model)

Right audio output - low level (this will drive headphones but NOT a speaker on this model)

2 pin DIN (flat & round)

SPECIAL NOTE: The model 9500 does NOT have the full audio amplifier installed. Looking at the schematics, it appears the 2x AD150's (push-pull output) are not included. Only the 10,000 model has the full audio amplifier installed. This is why the DIN output sockets can only provide drive for headphones.

External control socket - this is used with optional extras (not supplied)

6 pin DIN female

There are 4 heads installed (yes 4) and these allow for special recording/playback facilities

2x Record/Playback heads

1x Dia-Pilot head (used for the slide sync functionality)

1x Erase head

These special tape facilities include:

2 track OR 4 track operation - the head mount is user changeable to switch between these two options of "laying down" your tracks

Tape echo functions

Tape multiplay - this is where the user can superimpose new recorded material onto material that has already been recorded to the tape

Dual monitoring: the user can either listen to material BEFORE it goes to tape OR after it has been recorded on the tape

User set screw adjustment of the playback head (used to allow for tapes recorded on other machines that are not correctly aligned)

Many optional extras were available for this 9500:

Telephone recording adaptor 802G

Aukustomat 817 (used to sync this machine with a slide show presentation)

Remote Control Switch 656

Remote Control Foot Pedal 696

I AM NOT INCLUDING THESE OPTIONAL EXTRAS but mention them to illustrate how the functionality of the machine could be expanded (if you could ever find this optional equipment)

I will be supplying the user manual (very handy), service manual (for restoration or repair), schematics (clear and readable)

All documentation is supplied in hardcopy, not on a CD

MACHINE COSMETIC CONDITION:

Overall, very good condition

BASE (high impact plastic)

Secures to the main unit with 4x screws - very easy access to the underneath electronics/mechanical system

NO cracks

Slight/light scuff marks - to be expected as this is the base

NO missing pieces EXCEPT 3 of the feet inserts are missing (probably fell out) Look at the photograph, a rubber foot sits inside the foot support on the base and 3 of these are empty. Still useable but the machine cannot sit level on a surface when these 3 are missing.

It appears to me that there should be a hinged cover over the power cable/input-output area (there is a hole on each side which look to be for a pin type of hinge) - this hinged cover is long gone. If there was such a cover, it would have been a nuisance anyway because it would obstruct access to the input-output sockets

The central slotted hole sits directly over the rear of the motor. Originally this had a foam ring between the motor and the plastic base but this foam has completely deteriorated so I have cleaned up the remnants otherwise they may fall into the open rear of the motor. For the sake of authenticity, a new foam ring could be fashioned very easily and glued into place.

There is a long rectangular piece of foil inside the base, it sits directly over the audio board (for shielding) and is grounded via a brass spring clip that makes contact when the base is fitted and secured.

INTERNAL ELECTRONICS/MECHANICALS (viewed from underneath)

Very clean and tidy! No-one has been in here for 50 years, that is obvious. No mods, no obvious component failures. Toothed drive belt from the central motor feels good (good tension) and does not appear to have deteriorated over the years. Love that cable lacing (a very common practice in electronics at this period) but a dog if you wish to get into the wiring for some reason.

All components are discrete, no integrated circuits here! Looking at the schematics, this machine uses a mix of silicon BC series transistors in the audio sections and some germanium (2x AC153 & AUY21!) in the power supply (regulation)

Electrolytic capacitors are always a worry in equipment this old, on the audio board Uher has used what appear to be German (Siemens?) EKT, ER series capacitors (they look more like small inductor cans) and I strongly suspect these are special long life capacitors (50,000 hours MTBF) This would be in line with Uher's machines having a high reliability reputation.

The power supply sub board does have more "normal" looking electro's although these are under a cover so I cannot identify the manufacturer properly. In light of the issue mentioned further down in this description, these electro's could be suspect.

Other caps on the boards are styro's, polyester - all nice stable capacitors.

A quick look at the "above board" wired resistors shows these to be 1% tolerance, probably metal film.

TOP SIDE

CLEAR PERSPEX LID

Hinged/lift off for easy removal

Metal sides and front/rear into which the perspex lid is "slotted"

Each side has a spring loaded clip - both are working fine

Rear has two metal "hooks" which are in good condition (although light corrosion to the chrome plating is showing) and on one hook there is ONE screw missing. It is a very small screw but shouldn't be hard to find a replacement. This hook is still secure in place with this one screw missing.

Perspex has NO cracks or bad markings

There are scuff marks (light) which I am told can be "polished out" It looks pretty good just as it is but if you wished to produce a pristine finish, this seems to be achieveable.

The side metal strips (with the slots) had some type of powder coating (I think) and this has deteriorated quite a bit - again it doesn't look terrible but perhaps it can be recoated, I am not sure about this.

MAIN BODY (veneered timber outer case, the remaining case parts are metal with the exception of the perspex hinged lid

TIMBER OUTER CASE

MDF based with a nice, high quality woodgrain veneer - matt finish. I have seen a lot of veneers in my time and this would have to be one of the best - nice piece of furniture!

No marks on any side, very clean and good looking.

I have applied a nice wood oil to this casing (timber veneer doesn't like to be too dry) and it has come up beautifully.

The MDF is showing NO signs of dampness (it will expand after getting wet) or crumbling

The top of the case has 4x button feet. 3 of these are fine but one has lost the plastic outer ring which means it will sit unevenly on a flat surface. Two options here, either remove the other plastic surrounds or find another plastic ring.

This area is also where the Uher product ID badge is located.

FRONT OF DECK

Very good cosmetic condition overall

NO buttons/knobs missing

NO damage to any of these items

Head assembly (two parts - front and head stack proper) is in excellent condition

Spindles are both in great shape, twist & lock reel system working fine.

The knobs for the level and volume are all concentric types, meaning the lower and upper sections move independently of each other (for each channel). I noticed some of the adhesive inside the top knobs had "dried up" so the knob wasn't as secure as it might be - a drop of adhesive inside the knob will fix this.

The "switching" knobs such as audio system select, speed and tape transport control are all in excellent condition, no splits.

All knobs are pull off and push on, there are no grub screws

VU meter (with the blue playback and red record lamps on each side) is clean and the pointers are at rest, where they should be.

Tape travel counter window has a slightly blurry look to the left-hand side, tried cleaning but this dirt seems to be inside the window.

One very small cosmetic damage noticed, near the level control knobs on the left-hand side is a small "nick" in the edge metal. It is really small and can be felt "to the touch" so I am making you aware of it.

HEAD ASSEMBLY IN DETAIL

The head assembly fitted is part number Z 324 4 Spur Stereo (meaning 4 track Stereo)

I must say I was astonished at the head condition - very very nice. The gaps are clean and shiny, wear is not much at all and of an even pattern. This applies to both R/W heads, which are BORGEN manufacture - this company still seems to be in the business of magnetic heads although not for tape recorders of old.

The other thing that I noticed immediately is the beautiful engineering, just unscrew two large diameter knobs (you can see them in the photographs) and the head stack just lifts off. This makes for very easy inspection and cleaning. While I had them off the deck, I also demagnetised the heads.

The other critical component is the pinch roller and this also astounded me, the condition is amazing for such an age. The rubber roller does not appear to have "flat spots", is NOT hard (I can feel a nice rubbery feel between my fingers but not spongy!) I gave the pinch roller a quick clean (non-alcohol, NEVER use alcohol on your pinch rollers) and just a small amount of rust (oxide) came off on the cloth - again indicating not much tape has gone through these heads.

The headstack was so clean, I don't believe this machine had a lot of use in the past. Normally there is all sorts of oxide powder and tape debris inside the head stack but none on this one.

Both tape tension arms move freely and the tape guide path is clean and shows very little wear.

The only thing I did notice is some "peeling" of this coating that Uher put on the head stack frame - over where the tape exits the pinch roller, you can see some of this coating is missing.

TESTING - FINALLY!!!

As you may have guessed, I have spent HOURS checking over this machine (at times thinking that perhaps I should hold onto it!) but now it came time to test it - I wasn't expecting much, it has been out of service for a long long time.

First up, the primary AC fuse was missing! Not blown but physically removed. The fuse is supposed to be a 630mA Slow Blow but I only had a 400mA Slow Blow so that is the fuse I used for testing - that 400mA fuse will be supplied installed but remember to upgrade the fuse to the correct type ASAP otherwise you are likely to have the machine suddenly stop on you!

The required fuse is 630mA Slow Blow type 2AG

My under-rated 400mA fuse held out fine for all of the testing so the equipment is not drawing excessive current.

NO funny smells! Certainly no burning or "pop" sounds (like an electro exploding!)

I loaded up the tape (the tape you see in the photographs WILL be supplied with the machine - material on the tape is unknown, I just grabbed a spare couple of reels for testing)

Setup the controls for running at 7.5 ips and away we went .... yes, there is motion! Actually it runs very smoothly, no issues here at all.

I then stopped the tape transport and switched to every other speed, all worked fine - the slowest speed is so incredibly slow!

On playback the tape moved smoothly, tape tension was correct (not stretched or slack) and all was good with the world!

Tape travel counter works fine, it moves evenly in unison with the tape movement and the large reset button brings the count immediately back to 0000

But dreams are made to be broken ...

HERE IS ISSUE #1

Then I noticed something was not right - the VU meter is not moving (both channels) and the Blue Playback lamp is not indicating. So something is wrong here. I also switched to Record and the Red Record lamp also does not indicate.

I was going to leave it "as is" (I have spent hours on this and I don't really want to restore the machine!) but curiosity got the better of me. I had another look inside, particularly at the power supply board. It is only then that I noticed both of the low voltage rail fuses had "disintegrated" in their holders - not due to excessive current but I guess they have just failed over time. As I removed both fuses, the end caps just fell off! Next I spent a lot of time hunting around my spares for a couple of fuses (160mA Slow Blow & 1.6A Slow Blow) I have a lot of spare fuses but these (for me) are weird values so for the purposes of testing I grabbed a 250mA & 2A fuse and crossed my fingers!

All went well and now both the Playback and Record lamps illuminate. However still no VU meter readings and no audio that I could find on the DIN output socket.

While I was inside the machine I measured the voltage across C31 (easily accessible) and it is sitting at 36V - spot on what it should be. I made no further voltage tests on the power supply board, it would have mean't dismantling the PSU mountings and pulling out the board - I am simply not inclined to do this. At least I had one correct voltage, and the schematics (supplied with this equipment) are clear and indicate various voltage test points - so fault finding should not be a difficult task. I noticed that the supply rails go to the large rotary switch, so again this comes back to probably a decent cleanup with switch cleaner could well solve all problems.

My two fuses used for testing have been removed so the new owner must get themselves a 250mA & 1.6A Slow Blow fuses (2AG) before they can start the restoration process (looking down on the board, the 160mA fuse is in the top holder and the heavier current fuse below that).

The large multi-gang rotary switch (controls ALL the audio switching functions) has NOT been cleaned and as it is an open frame style of rotary switch, this would be a prime candidate for problems (wiper or track oxidisation) - it could very well be that a decent squirt with switch cleaner will solve any audio problems.

Also note that the push button controls (monitor etc) are also open frame style which most likely need a good switch cleaner applied as well.

HERE IS ISSUE #2

The other issue is the Fast Forward/Fast Rewind function (small horizontal slide button which sits below the tape transport control) - the tape does NOT move in either direction, the motor is running and I can hear quite a bit of mechanical type noise inside but no movement from the reel tables.

While checking out the power supply (partially) I took a look at what is happening when FF/RW is engaged. The long control arm moves into position correctly but then for some reason, the various wheels with tyres and not engaging or at best, partially engaging. This is some sort of mechanical issue and I have proceeded no further to find out what is wrong and how to fix the problem.

I am not about to start servicing/restoring the machine, I have already decided it will go to a new owner and I am not about to spend more time restoring the machine myself.

NOTES ON SHIPPING:

I am perfectly able to ship this equipment safely, within a strong box and padded with bubblewrap and styro sheeting. Shipping within Australia or internationally is no problem at all

My website only provides Australia Post quotes automatically but I can also manually quote shipping via a courier (sometimes faster, sometimes lower cost) - just ask me for a quote by courier.

To reduce the cubic volume of the package, the carry handle will be taken off the case (very easy to re-instal)

Special attention will be given to the top perspex lid to ensure no damage occurs while in transit